Batch process

Technical Features

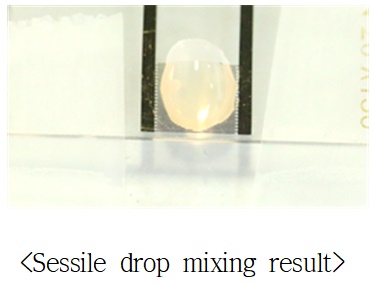

Nano/medical devices based on microfluidics are gaining attention as a next-generation bio/healthcare diagnostic and precision medical platform. This is because the technology to precisely control samples in liquid human specimens such as blood, urine, sweat, saliva, and samples in liquid samples is expected to play a very central role as a next-generation healthcare platform. The process technology, which is a core element of nano/medical devices, such as mixers and heaters that can perform basic roles such as fine concentration and temperature control of biochemical reactions needed at this time, is the reason.

By securing the technology to design/manufacture/evaluate module chips through the modularization of nano-medical device components, it can be used for research and development and commercialization of various nano-medical devices.

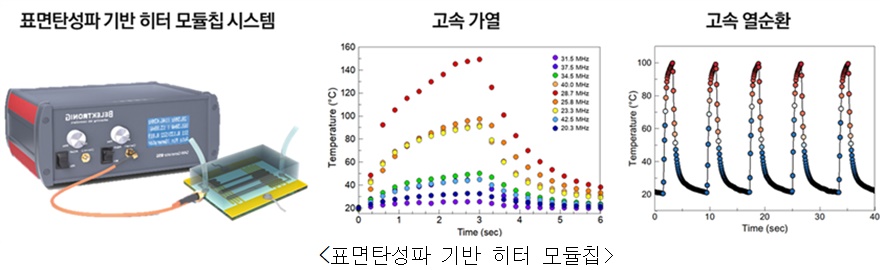

When a MHz band Rayleigh surface elastic wave is applied to a polymer with high viscoelasticity, viscoelastic damping occurs due to internal friction between viscoelastic networks, and as a result, acoustic energy is converted into thermal energy, causing rapid body heating. In addition, by constructing a surface elastic wave generation part based on a slanted bar electrode with a wide resonance frequency band, it is possible to form a microscale temperature distribution.

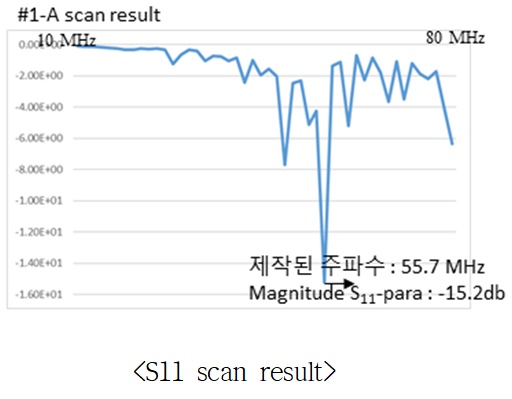

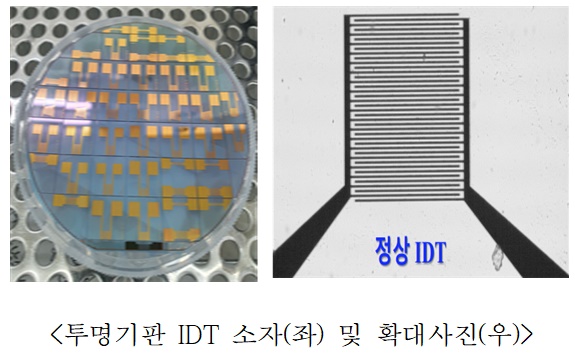

Completion of IDT (InterDigitized Transducer) process and device development and application

Completed improvement of substrate crack-related problems

Completed adhesion problems between substrate and electrode

All crack problems solved according to other process conditions